The manufacturing of aluminium Sulphate

Aluminium sulfate, Al2(SO4)3, is widely used by various industries in India. Its most common applications are in the pulp and paper industry and in the purification of water. In both these instances alum is used as a source of Al3+, a highly charged ionic species. Negative particles, such as those which discolour our raw water supplies, are attracted to this cation, react with it and then precipitate out of solution as ionic solids. Alum (as aluminium sulfate is commonly called) is manufactured in a simple two-step process from aluminium trihydrate and sulphuric acid according to the following reaction:

2Al(OH)3 + 3H2SO4 + 8H2O → Al2(SO4)3 .14H2O ΔfH = -156 kJ mol-1

Introduction

Aluminium sulfate (Al2(SO4)3), commonly called alum, is produced as white crystals which are non-combustible and soluble in water. This dry hydrate (Al2(SO4)3.14H2O) is 17% Al2O3 and is also sold as a 47% w/w aluminium sulfate solution which is 8% Al2O3. It is also sold in solid form as kibbled, ground or dust. Uses of aluminium sulfate has been used by man since 2000 BC, when the Egyptians used a mineral alum as a mordant in dyeing. It has long been used in paper sizing to improve durability and ink receptivity and in water treatment to clarify water. Other uses for alum include wastewater treatment, as a waterproofing agent and accelerator in concrete, as a clarifier for fats and oils and as a foaming agent in fire foams. The aluminium ion has a high charge, which makes it an excellent coagulant for colloidal1 matter. This property means that alum can be used to remove particles from water. The free Al3+ ions hydrate to form highly charged species such as Al8(OH)20 4+. These are attracted to negatively charged species, which include the most common colloidal species in water: 1 A colloid is a system in which one substance is finely divided up within another system, e.g. fog is a colloid of water droplets finely divided up within the continuous medium of the air, and milk is a colloid of fat globules finely divided up within an aqueous solution. In paper making, the alum reacts with rosin sizes of various types, helping to attach the newly formed rosin aluminates to fibres. Sizing makes the paper water resistant. Alum, which exhibits a cationic charge, is also used to flocculate anionic trash including paper fines and other anionically charged material by neutralisation, in a similar way to water treatment, improving drainage, retention and strength of the material.

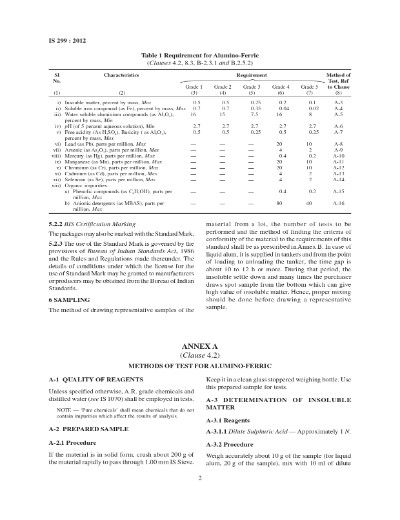

| Type | About |

|---|---|

| FERRIC ALUM GRADE 2 ALUMINA 15% (COLOR YELLOW) | We are counted amongst the foremost manufacturers, trader and suppliers of Ferric Alum to our esteemed clients. Our ranges of chemicals are widely used in water purification, paper, steel, automobiles etc. These are composed using top quality chemicals and latest technology and are appreciated for properties such as high purity, accurate composition and longer life. We supply these chemical to our respected clients at affordable prices in the market. |

| FERRIC ALUM GRADE 2 COMMERCIAL ALUMINA 12% (COLOR GREY) | In an investigation of the properties of alumina GO, GK, and GU of Soviet origin and of the Hungarian alumina GV it was shown that the chemical composition is similar in all these materials but the alkali content is highest in the Hungarian alumina. |

| FERRIC ALUM GRADE 4 ALUMINA 16% (COLOR WHITE TO BROWN) | Water Treatment Purifiction,Reduce High Turbidity From Raw Water and Drinking Water Filter Plants |

| FERRIC ALUM NON - FERRIC ALUM (COLOR WHITE) | We are one of the most reputed firms involved in offering a comprehensive range Non Ferric Alum. It is also used in purification of drinking water in industries. They are soluble in water have an astringent acid, sweetish taste, react acid to litmus. Our product range is procured in compliance with variegated demands and needs of our client base. These are available at a cost effective price in the market. |

| POTASH ALUM | It is a chemical compound: the double sulfate of potassium and aluminium, with chemical formula KAl(SO4)2. It is commonly encountered as the dodecahydrate, KAl(SO4)2·12H2O. It crystallizes in cubic structure with space group P a -3 and lattice parameter of 12.18 Å.[5] The compound is the most important member of the generic class of compounds called alums, and is often called simply alum. |

| AMMONIA ALUM | Ammonium alum is not a major industrial chemical or a particularly useful laboratory reagent, but it is cheap and effective, which invites many niche applications. It is used in water purification, in vegetable glues, in porcelain cements, in deodorants and in tanning, dyeing and in fireproofing textiles. The pH of the solution resulting from the topical application of ammonium alum with perspiration is typically in the slightly acid range. |

| LIQUID ALUM | Liquid Alum is a clear, light green to light yellow aqueous solution. Iron-free liquid alums is clear and colorless. Dry Alum is pale green to white in color and is available in powdered and ground forms. It can be dissolved in water to produce a solution. |

Packaging Details

| Size | Price | Packaging |

|---|---|---|

| 25 Kgs | Rs. 6 ~ 16 | Loose |

The Manufacturing Process

The aluminium trihydrate is transported and stored in one tonne bags. Each bag is carried by hoist to the feed hopper, where it is opened and conveyed to the reaction tank. The reaction water, trihydrate and sulphuric acid batch is stirred for a period of time with water vapour exiting through the stack.

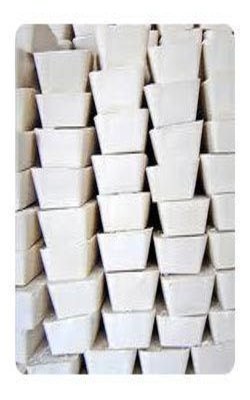

After the reaction period, either liquid or solid alum is made. If liquid, the concentrated batch is run into the dilution tank filled with the dilution water, where it cools over time. The liquid alum is then filtered and pumped to storage. If solid is made, the concentrated alum is run into the casting pans where it sets, aided by fan cooling. The pans are forklifted to storage racks and from there they are taken to the Crushing Plant and dropped into a hopper. The pieces are broken further by a large kibbler followed by a small kibbler and then screened. Oversize particles go to a bagging hopper and are sold as kibbled product. The screened alum is rotary crushed and further screened to either return to the rotary crusher or be bagged as ground product. Dust is continually collected through an extraction system and is sold as product. The Crushing Plant is flexible and the ratio of kibbled to ground aluminium sulfate is variable.